Early lessons from those delivering apprenticeships

This Autumn, I’ve been running CPD days for those on the front line of delivering apprenticeships. These are small-group events where we’ve looked across the whole apprenticeship process focussing on the learning journey, end-point assessment and quality assurance.

Below – in no particular order – are some of the issues discussed by participants and ways in which these are being addressed:

1. 20% Off-the-job training: How flexible is flexible?

With the introduction of the new EIF and Ofsted’s changing focus, it’s important to define the blend of learning approaches and contexts that may ‘count’ towards the 20% from a teaching, learning and progress point of view.

There are flexible ways of approaching the 20%, but you need an understanding of how a work-based curriculum works, including the opportunities for learning presented by each individual workplace and practical strategies concerning what effective progress looks like within your specialist occupational area.

For example, which of these would you say counts towards the 20%?

- A health and safety session

- Introduction to care and use of tools and/or equipment at induction

- Online learning package for apprentice to complete between taking calls in the call centre

- Distance learning modules to be completed weekly.

The answer is ‘it depends’.

Questions to ask are:

- Does it link directly to the standard?

- Does the apprentice have access to support in real-time?

- Where does learning take place and in whose time?

As an Ofsted inspector pointed out to us:

“You need to be careful: we would consider blended approaches very much as ‘value added’ but if the whole 20% curriculum takes place in this way we would be thinking more in terms of cutting corners, particularly if the apprentice can’t articulate their learning and progress.”

2. Planning and delivery

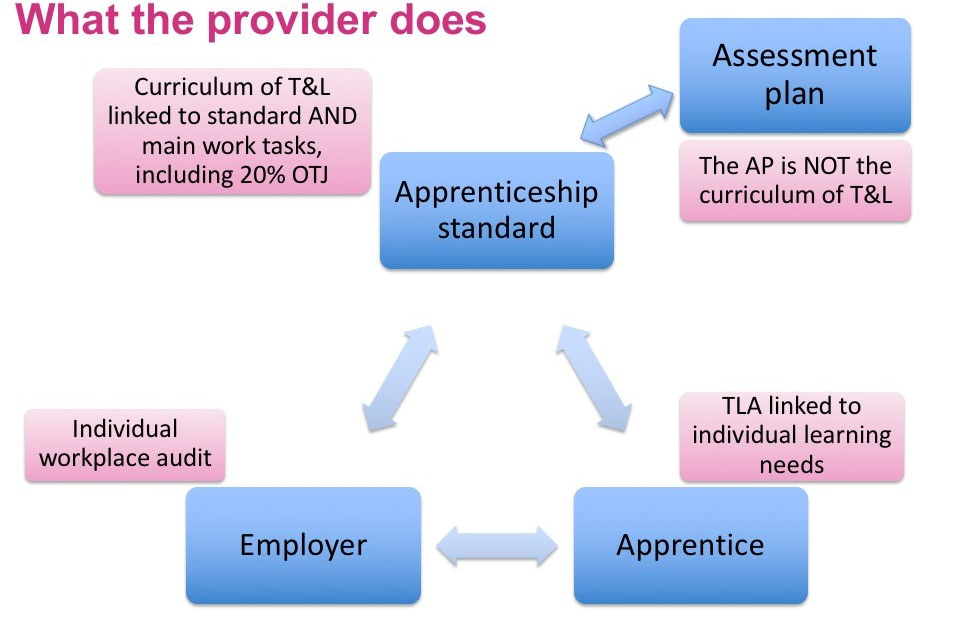

Curriculum planning of apprenticeships needs to take account of the employer’s context, the apprentice’s learning needs, and the standard. It looks like this:

Some participants report little or no flexibility to plan their curricula: some are given teaching slots on a daily or weekly basis with no reference to employers, learners, fellow teachers (such as functional skills tutors). Others are given the brief to deliver the standard with little support.

Given that most are trained teachers, this is a waste of professional expertise. It can also lead to de-motivated learners.

On the plus side, others reported more freedom to plan and prepare apprentices for EPA:

The standards I teach don’t have any qualifications as part of the gateway, so my life has got a lot easier. I love being able to teach to the standard from the industry’s perspective and not having to assess evidence.

Now that my first cohort has been through end-point assessment, I feel much more confident about the next one. Many actually said they enjoyed discussing the work they’d done. It’s not as though they didn’t know exactly what was coming – if anything, they were over-prepared!

3. Feedback on EPA for QA purposes

On-programme providers say it is important to gain feedback via the employer or directly from EPAOs. Participants whose apprentices have been through EPA are keen to find out details of end-point assessment beyond the grade achieved as this informs the QA process and enables the provider to pinpoint areas of teaching, learning and EPA preparation that could be improved.

Half of my first cohort gained distinctions and half of them passed even though I had nearly all of them on target for a pass. I don’t really know what ‘distinction’ looks like. I’d like to know what they did to achieve it.

Participants with strong links to their EPAO (such as those with EPAOs within their group of companies) report no difficulties in asking for sample assessment materials or feedback.

4. Dual professionalism and updating

There appears to be a lack of industry specialism on all fronts.

For example, participants are:

- Leading curriculum areas where they themselves had little or no experience.

- Working with team members who have no up-to-date industry experience.

- Responsible for the CPD of assessors and trainers, some of whom are reluctant to update either their teaching/assessing/QA expertise or their industry competence.

- Working with Ofsted inspectors with no experience of FE & Skills.

Some do not see any benefit in returning to industry:

“My team have been running xyz apprenticeship programmes for many years and we’re already the go-to provider in our specialist area. I can’t see what we would gain from going back into practice with the people we already train.”

5. Involvement of curriculum specialists from the start

In some instances, participants say it’s their sales team that takes sole responsibility for employer liaison and engagement:

Having attended today, I’m going to recommend we have someone from each curriculum area involved at the recruitment stage. It makes sense for them to do a workplace audit as they will be able to identify the learning opportunities and make recommendations for the 20%. It’ll help us adapt our curriculum planning as currently we don’t get to see the employer’s perspective!

In my view, you need TLA specialists involved at this early stage to inform joined-up curriculum planning and to build ongoing relationships with employers. The person with responsibility for managing teaching, learning and progress (if this is someone different) should also be involved from the start.

Hilary Read, Author and publisher of guides and e-resources for vocational teachers and assessors.

Please comment below if you would like to add your own experience, or contact Hilary directly.

If you or your staff would like to attend an event in the new year, all attendees receive a free copy of Hilary’s practical guide: The best assessor’s guide: apprenticeships edition.

- 15th January, London (Camden) with thanks to One Housing for the venue. Book your place here.

- 6th February, Birmingham (off M6) with thanks to The Apprenticeship Centre for the venue. Book your place here.

Responses