Why AR is the solution to solve the labour shortage

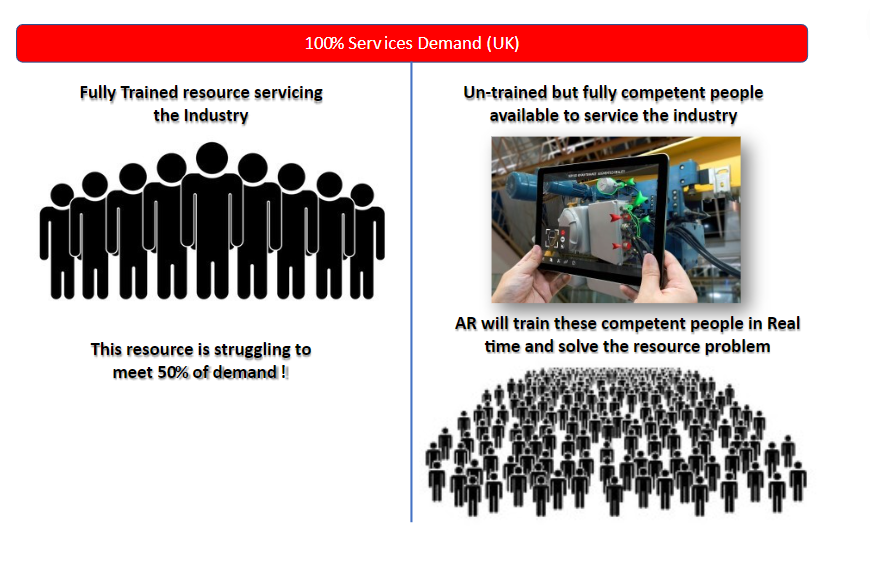

Service demand is surpassing resource by 50%!

Labour sourcing is one of the top obstacles for FM professionals. There simply aren’t enough engineers available to be called out for jobs. The end of the free movement following Brexit is just one factor affecting the UK labour market, together with the aftershocks of the pandemic and early retirement.

It’s estimated there is a shortfall of over 173,000 workers in the STEM sector: an average of 10 unfilled roles per business in the UK, which is costing the economy a shocking £1.5bn per annum. Additionally, 49% of engineering businesses are experiencing difficulties in the skills available to them when trying to recruit.

In response to the UK labour shortage, it’s become necessary for FM leaders to offer greater flexibility and to think creatively about their recruitment approach. Also, a lot of companies are simply paying higher wages to attract the talent they want, this just moves the problem around rather than solving it. We need to think differently about how to address the problem. Whilst the above factors are important, it’s crucial FM leaders upskill and reskill existing employees as well, ensuring the expertise is readily available. One way of doing this is through augmented reality (AR), a highly visual and interactive method of presenting digitised information in the context of the physical environment. AR democratises knowledge and enables connections and information sharing irrespective of physical limitations and distance. The pandemic has catalysed a digital world and the market size worldwide of the AR/VR/MR market is to rise to $300 billion by 2024, suggesting it will play a big role now and in the future.

What is AR and what are its benefits?

AR technology enhances what we can see in the present by integrating simulated information into the real world. With AR, you are immersed and have a deep experiential learning experience, meaning you’re more likely to recall what to do when the situation or challenge arises again. Studies have shown that AR/VR can train better than typical classroom learning as practical jobs require fast thinking based on previous experiences, all of which can be gained through simulated learning experiences. This improved learning capability is due to our brain’s ability to build a “memory palace” that organises memories spatially within an environment.

AR is therefore well placed to (re)train engineers in the FM industry as they can put their learning to the test virtually in the environments where they will be performed. Equally, if an engineer gets called out to do a job they are unsure of, a more skilled engineer can provide live annotations and notes to ensure the job gets done correctly without using more resources and having to call out a different engineer. While initially costly, AR can save training costs and travel expenses as AR sessions can be offered regardless of location, saving both time and money.

AR can train competent people who are able to service the industry

There are a tonne of competent people who have what it takes to fix things. By no means is everyone able to engage in complex jobs but there are a lot of people that can use a screwdriver.

Not every job an engineer gets called up for is complex. Sometimes it only requires a few simple, safe steps that anyone under guidance can do. So that’s where AR and VR can step in, to walk everyday people through repairs and maintenance with the help of an engineer virtually or easy to follow videos. This can be done by scanning the environment live through a mobile or tablet to provide real-time assistance. This could save a lot of time and, in turn, alleviate some pressure in the industry by helping reduce the backlog of jobs. Additionally, when there is a shortage of a particular set of experts, technology can help bridge the gap. For instance, a specialist fridge engineer is skilled enough to be able to fix an oven if walked through by another engineer virtually or a video. Two separate specialists on site aren’t necessarily required. It removes all geographical boundaries, talent from another country can help a UK engineer on a job virtually. This not only addresses the issue of them not being able to be in two places at once, but it can also reduce the carbon footprint of engineers, who are typically known to be called to jobs all over the country.

In the midst of FM’s changing work environments, labour shortages, and skills gaps, AR technology could be critical for training and improving operational efficiency and productivity. Not to mention the employee learning experience! AR makes it possible to narrow the knowledge gap, ensuring the workforce of today and future generations have the tools they need to succeed. Ultimately, AR can be used to upskill and reskill workers to combat the continuing labour shortage.

By Jeff Dewing, founder of Cloudfm & Mindsett

Jeff Dewing is a revolutionary tech innovator, the No.1 best-selling business author of Doing the Opposite, and founder of Cloudfm & Mindsett. Their Tech has disrupted a £200 billion industry and they’ve been named Queens Award winner for Innovation (2019) and a global leader in IoT-enabled predictive maintenance by Gartner.

Jeff left school at 16, working his way up the ranks as an engineer to owning a successful multi-million-pound business (and football club) but he lost it all, having only £7.60 in his bank account. Despite this Jeff, managed to turn his life around, learnt to code and started a new business from his garden shed building it to £70M turnover. He’s spearheading the technological revolution, now using game-changing tech to help businesses achieve net-zero and is projected to achieve £250M by 2026.

Responses