New packaging apprenticeship key to eradicating plastic waste and pollution

Recently the media has been shining a bright light on the role of packaging and its effect on the environment. In response, businesses across the globe have now pledged to make their packaging more eco-friendly.

But, up until now, the pipeline of talent involved in the creation of packaging has mainly come from overseas, with other countries affording greater opportunity to work on creating new effective and environmentally friendly packaging solutions.

We spoke to trailblazer, Bruce Funnell, Head of Packaging, Nestlé Confectionery Product Technology Centre, and Justine Fosh, Group CEO, the National Skills Academy for Food and Drink and Occupational Awards Limited, about what the new Packaging Professional Degree Apprenticeship will mean to the industry, apprentices, and the world at large.

Justine, why are people talking about careers in the packaging industry right now?

Programmes like Blue Planet have brought plastics to people’s attention. In fact, there has probably never been a more important time to attract talent to join the industry.

Because of the current concerns, businesses are now seeking new ways to make their packaging more eco friendly. In fact, this week, 250 organisations, (including many of the world’s largest packaging producers and retailers), signed a global commitment to eradicate plastic waste and pollution.This followed Nestlé’s recent announcement that it aimed to make 100% of its packaging recyclable or re-usable by 2025.

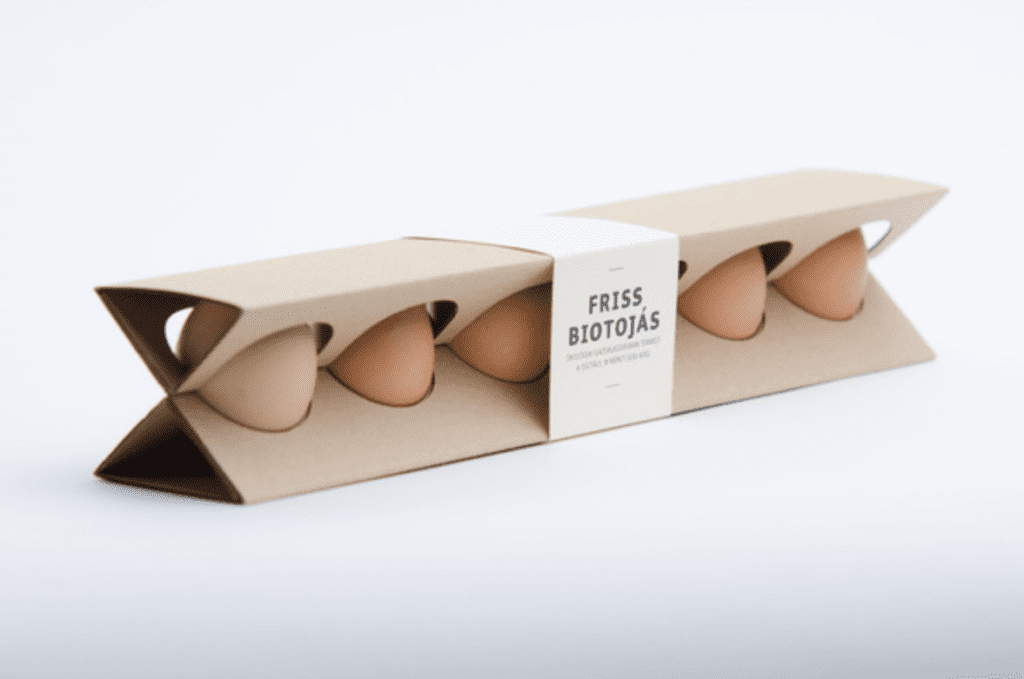

But, different products require different approaches and types of packaging, so there is a lot of work to be done in this area. Packaging professionals will now have a unique opportunity to be part of the whole sustainability movement. It’s these people who will be responsible for improving end to end design, developing new materials and processes – and ultimately contributing to a more sustainable future for all.

Bruce, do you think that people sometimes overlook the significance of packaging in our daily lives?

Yes, almost every aspect of our lives involves an engagement with packaging at some point. Effective packaging needs to ensure that products are fully protected and delivered in a safe and secure manner, and that product waste is prevented. Good packaging also needs to engage and inform consumers, whilst being affordable and transportable. But it needs to achieve all of this with minimal environmental impact.

Can you tell us a bit about what a packaging professional degree apprentice would be taught?

The apprentices will learn how to effectively design and develop appropriate packaging solutions, and how to put them through rigorous trials and testing, from production to delivery, through the supply chain.

They will also become proficient at working with a range of different teams including marketing, production, logistics and supply chain colleagues, as well as with suppliers and customers. They will develop vital technical knowledge, and be informed about different materials, and their various production methods. Throughout the apprenticeship, they will also be gaining project management skills and developing a commercial mind-set, both of which are hugely transferable.

Justine, how does the industry in general feel about these developments with degree apprenticeships?

There is a lot of excitement in the industry, as we have a desperate need to train packaging professionals. Currently, we often rely on skilled people from overseas, where there appears to be a greater talent pipeline, thus this apprenticeship development feels like a very important milestone.

Why go down the apprenticeship route?

Until now there was no real pathway through for packaging professionals in the UK. Few young people are aware of the great career opportunities available in this field, and therefore there is not the market demand for courses at Universities or colleges . Thus, the industry doesn’t have a pipeline of talent coming through ready trained for these highly skilled and important roles.

The only real option for our industry was therefore to train our own people. With no previous degree apprenticeship there were only occasional courses available and these often lacked employer input into their design . Therefore the industry recognised the need to come together and design a fit for purpose packaging apprenticeship that delivered people with the skills we all needed.

So Bruce, what is the plan now?

A standard is just the start point. If this is to translate into excellent training, we need to find high quality, committed universities to offer the apprenticeship. Without this, the standard means nothing.

Who has been involved in creating this apprenticeship?

It was NSAFD who originally put together a group to develop the apprenticeship. This consisted of employers from Food and Pharma as well as the packaging design, development, manufacturing and supply chain sectors. Driving change requires industry leadership, and Nestlé stepped up to be Chair, with 3M as Vice Chair of the group. We were all aware that we could only achieve success by working together. Thanks to NSAFD, we were able to work with like-minded employers, who all faced similar challenges.

Responses